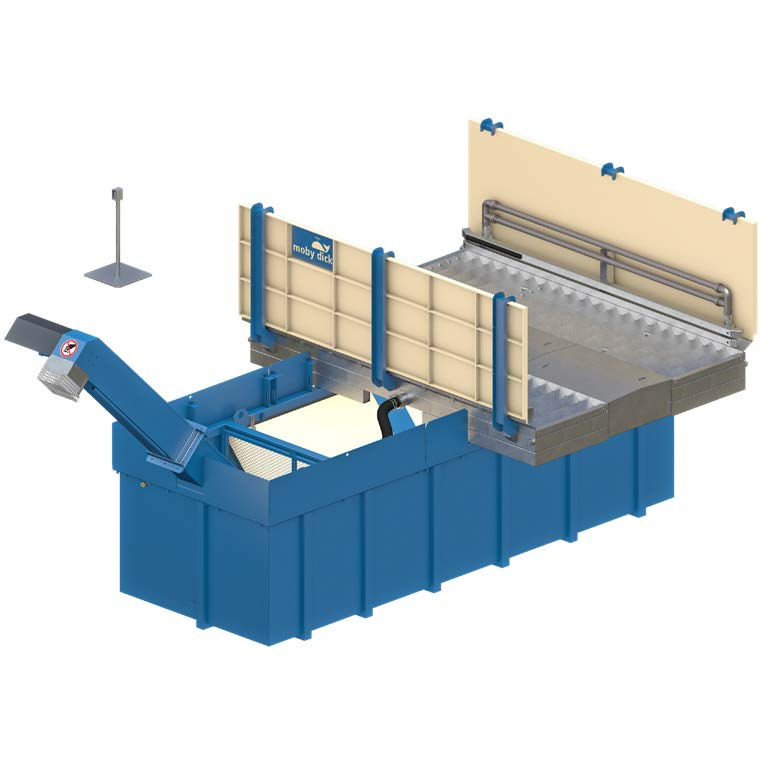

Mobydick Conline Kit Flex 400C

HIRE - PURCHASE - LEASE

World Leading Mobydick Truck Wheel Wash Systems

Effective Washing Technology

Water treatment is via

sedimentation in the recycling tank. Sedimentation can be accelerated by adding a flocculant. The solids that settle out in the recycling tank should be extracted with an excavator or suctioned out with a suction vehicle at regular intervals (depending on how frequently the system is used).

100% Water Recycling: includes full water recycling tank

The Unit has 4m Wash Platform Length: allowing full tyre rotation

Low Spray Fan Area: keeping drivers windscreen clear & safe

Low-pressure - High-volume Pump

Sensor Start/Stop

Can Wash Up To 150 Trucks Per Day

Includes Scraper Conveyor

The modular concept for the construction industry

Specs | Quantity | Unit |

|---|---|---|

Length of wash unit | 400 | cm |

Clear drive through width of the wash unit (lane) | 280 | cm |

Maximum axle load | 16.5 | t |

Height of splash protection side walls | 137 | cm |

Nozzles (Core diameter min. 7 mm) | 130 | Pcs |

Nozzle bars per side | 2 | Pcs |

Recycling tank volume | 18 | m³ |

Usable volume of operating water | 16.9 | m³ |

Sedimentation area of the recycling tank | 13.0 | m² |

Maximum pump performance | 2x 2500 | l/min |

Connected electrical load of the entire system | 11.2 | KW |

Sound emission | < 75 | dB |